In today’s fast-paced environment, logistics businesses are constantly looking for ways to improve efficiency and accuracy. Digital inventory technology has emerged as a game-changer in this sector. This article will share how these advancements are changed and enhanced the industry.

The evolution of digital inventory technology is significantly impacting logistics businesses. This transformation is driven by the need for greater efficiency, accuracy and real-time data management. By adopting these technologies, companies can stay ahead in a competitive market.

The Importance of Digital Inventory Technology

One of the key reasons why digital inventory technology is important is its ability to enhance operational efficiency. With automated systems, you can track and manage inventory in real-time, reducing the risk of human error. This not only saves time but also ensures that your business runs smoothly.

Additionally, digital inventory technology provides valuable insights into inventory levels, helping you make informed decisions about stock replenishment. This means you can avoid overstocking or understocking issues, which can be costly for your business. For moving insights, continue reading so that you can optimize your supply chain and improve overall productivity.

The integration of digital inventory technology with other systems such as warehouse management and transportation management systems further streamlines operations. This seamless integration allows for better coordination between different aspects of the logistics process, ensuring that everything runs efficiently.

Digital inventory technology also plays a crucial role in enhancing sustainability efforts within the logistics industry. By optimizing inventory levels and reducing waste, businesses can significantly decrease their environmental footprint. This technology enables more accurate demand forecasting, which leads to less overproduction and fewer expired or obsolete products.

By streamlining operations and reducing the need for physical paperwork, digital inventory systems contribute to a reduction in resource consumption. As sustainability becomes increasingly important to consumers and regulators alike, adopting these eco-friendly practices can give logistics businesses a competitive advantage while contributing to global environmental goals.

Relevance to Current Logistics Trends

The relevance of digital inventory technology in today’s logistics landscape cannot be overstated. As e-commerce continues to grow, the demand for efficient and accurate inventory management has never been higher. This technology enables businesses to keep up with the increasing volume of orders and ensure timely deliveries.

What’s more, digital inventory technology helps in maintaining transparency across the supply chain. By providing real-time data on inventory levels, it allows all stakeholders to stay informed about stock availability. This transparency fosters trust between partners and enhances collaboration.

In addition to improving efficiency and transparency, digital inventory technology also plays a crucial role in reducing operational costs. Automated systems minimize the need for manual labor, leading to cost savings. Moreover, by optimizing inventory levels, businesses can reduce storage costs and avoid wastage.

The pandemic has further underscored the relevance of digital inventory technology in logistics. With disruptions to global supply chains and rapid shifts in consumer behavior, businesses equipped with advanced digital inventory systems were better positioned to adapt. These technologies enabled companies to quickly reallocate resources, identify alternative suppliers and adjust to new patterns of demand.

As the logistics industry continues to navigate uncertainties, the ability to maintain visibility and control over inventory through digital means has become not just an advantage, but a necessity. This trend is likely to continue, with more businesses recognizing the critical role of digital inventory technology in building resilient and flexible supply chains.

Benefits for Logistics Businesses

The benefits of digital inventory technology for logistics businesses are numerous. One significant advantage is improved accuracy in inventory tracking. With automated systems, you can eliminate manual errors and ensure that your records are always up-to-date.

This accuracy translates into better customer service. When you have real-time data on stock levels, you can provide accurate information to your customers regarding product availability and delivery times. This enhances customer satisfaction and builds loyalty.

Another benefit is increased agility in responding to market changes. Digital inventory technology allows you to quickly adapt to fluctuations in demand by providing insights into buying patterns and trends. This agility gives your business a competitive edge in the fast-paced logistics industry.

Digital inventory technology also offers significant benefits in terms of regulatory compliance and risk management. In industries with strict regulations, such as pharmaceuticals or food logistics, these systems can automatically track and document important information like expiration dates, batch numbers and storage conditions. This not only ensures compliance with regulatory requirements but also facilitates faster and more efficient recalls if necessary.

By providing a clear audit trail, digital inventory systems help businesses mitigate risks associated with fraud, theft, or errors. This enhanced control and visibility can lead to reduced insurance costs and improved relationships with regulators, further contributing to the overall success and stability of logistics businesses.

Future Prospects of Digital Inventory Technology

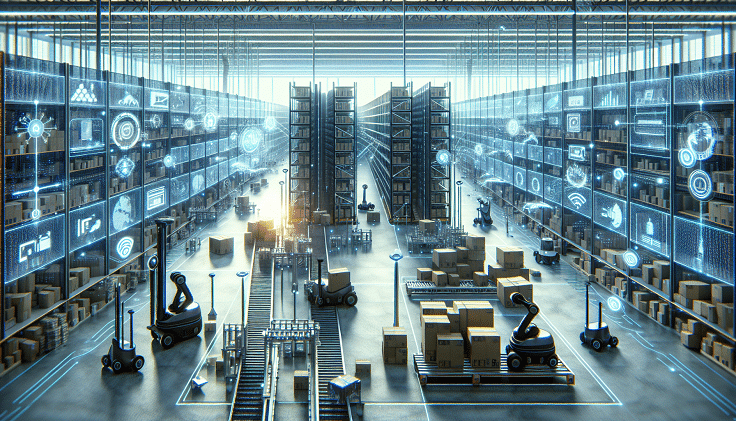

The future prospects of digital inventory technology are promising as it continues to evolve and integrate with other emerging technologies such as the Internet of Things (IoT) and artificial intelligence. These advancements will further enhance its capabilities and provide even more benefits for logistics businesses.

For instance, AI-powered predictive analytics can help you anticipate demand patterns and optimize stock levels accordingly. Similarly, IoT devices can provide real-time monitoring of inventory conditions, ensuring that products are stored under optimal conditions throughout the supply chain.

As these technologies become more sophisticated, they will enable logistics businesses to achieve greater efficiency and accuracy in their operations. By staying ahead of the curve and embracing these advancements, you can position your business for long-term success in the continually evolving logistics landscape.

Wrapping Up: What the Future Holds

Looking ahead, the integration of blockchain technology with digital inventory systems represents an exciting frontier for logistics businesses. Blockchain can provide an immutable, transparent record of all inventory transactions, enhancing trust and traceability throughout the supply chain. This could be particularly valuable in industries where provenance is crucial, such as luxury goods or organic produce.

The use of augmented reality (AR) in inventory management is also gaining traction. AR can assist warehouse workers in locating items more efficiently, potentially reducing picking errors and improving productivity. As these technologies mature and become more accessible, they have the potential to further revolutionize inventory management, offering logistics businesses new avenues for innovation and competitive differentiation.